Description

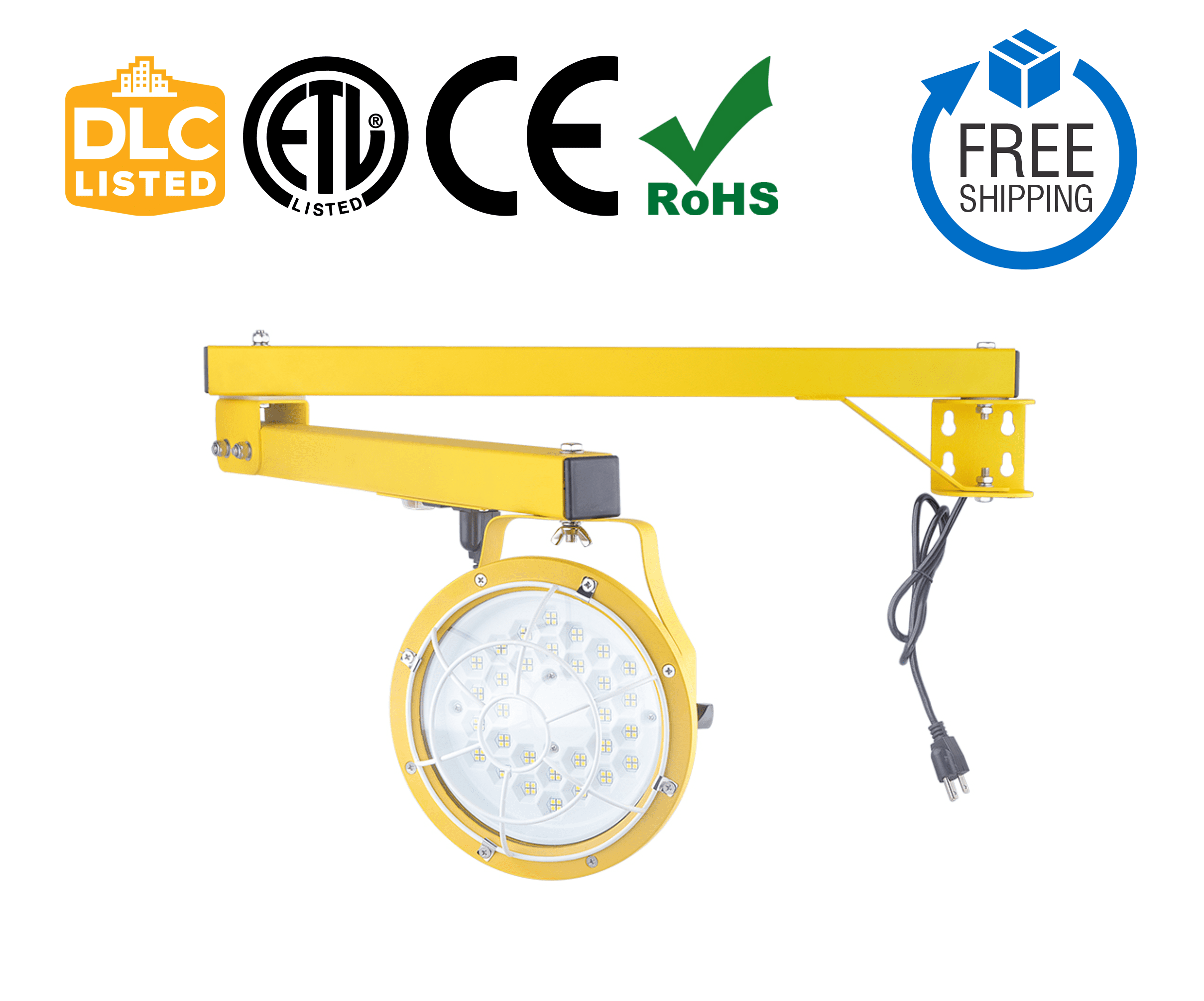

- Reliability: LED dock light is high impact resistant with robust structure, polyester powder coated finish for long term use in high temperature and corrosive environments

- Safety: Dust proof and water proof

- Energy-saving: High efficiency semiconductor LED technology, saves 70% compared to traditional light sources

- Economy: Long lifespan LED SMD, maintenance free

- Convenience: Adjustable swiveling U-bracket mount

- Excellent optical performance using highly reflective high transmittance lens

- 50,000 lifetim

- 5-year warranty

Specifications

| Power | 30W/50W all in one |

| Model | BB-MTD-30W/50W-2in1 |

| Luminous Flux | 30W=3900lm;50W=6500lm |

| Replacement | 30W=HPS 100W;50W=HPS 150W |

| Product Size | Ø Lamp size: 205*124mm |

| Mounting Type | Wall mount |

| Accessories | Steel mesh shield |

| Light Source | SMD LED |

| Luminous Efficacy | 130lm/W |

| Operational Temperature | -40° to +45°C |

| Color Temperature (CCT) | 3000K/4000K/5000K All in one, Options:4000K/5000K/5700K |

| CRI | 80+ |

| Lifespan | 50,000 at 25°C |

| Voltage | 100-277VAC/50-60Hz |

| Driver | Built in power supply |

| Dimming | No |

| Color | Yellow |

| Cover | Clear glass |

| Beam Angle | 120° |

| IP | IP65 |

| PF | >0.95 |

| Certification | ETL / CE |

| Warranty | 5 Years |

Download Product Cut Sheet

Knowledge Base

How do loading dock lights work?

Once the truck trailer has been unloaded, the inside light will turn to red, indicating to the forklift driver they need to stay clear of the truck. Simultaneously, the outside light will turn green, indicating to the truck driver that it is now safe for them to pull away from the dock.

What is the difference between a loading bay and dock?

Loading docks and loading bays are terms that are commonly interchanged for one another; however, while loading bays typically refer to a general area of a facility, a loading dock is the actual platform to which a truck or other vehicle connects to in order to unload

What is considered a loading dock?

A loading dock or loading bay is an area of a building where goods vehicles (usually road or rail) are loaded and unloaded. They are commonly found on commercial and industrial buildings, and warehouses in particular. Loading docks may be exterior, flush with the building envelope, or fully enclosed.

Why are loading docks angled?

A sawtooth loading dock consists of several smaller docks, with each dock positioned at an angle. This helps to save space outside of your facility, allowing you to load more vehicles at a time.

What are the OSHA requirements for loading docks?

A company’s loading dock safety checklist must include safety barriers. According to OSHA standard 29 CFR 1910.28(b)(1)(i), a dock that creates a drop of four feet or more must be guarded with a barrier. Chains are one-way employers can create a barrier, but bars are often recommended.

Do I need a loading dock?

A well-designed loading dock can also help reduce the risk of accidents and injuries, providing a safe and secure area for workers to operate in. Whether you are running a warehouse, a manufacturing facility, or any other business involving moving goods, a loading dock is an essential part of your operations.